Conveyor belt manufacturers in India: a partnership with an Indian OEM, M/S Chanderpur

SIG and ELEMET: Italian Technology Supporting India's Cement Industry

Steel cord belts for bucket elevators are an extremely important item for the cement industry since they are installed inside heating towers to allow proper cement production. These high-tech items surely form part of SIG range of products, named as ELEMET, they have been supplied worldwide always meeting customers’ expectations and assuring excellent performances.

Notwithstanding, we can easily state that thanks to a long-lasting strategic partnership with an Indian OEM, M/S Chanderpur, SIG has provided to a huge number of cement plants based in India its technologically advanced steel cord belts for buckets elevator systems.

Before deepening the topic about the most important supplies accomplished in that country, it is crucial to focus on some technical aspects connected to ELEMET carcass construction.

First of all, it is possible to identify two different types of steel cord belts for buckets elevator systems:

• ELEMET, which is the standard construction, produced with one warp and two wefts. It is characterised by thinner, more elastic and low elongation steel wires;

• ELEMET LE is SIG new inner carcass construction for buckets elevator systems. If compared to traditional one, this stands for a revolutionary item as it is composed of one warp of regular cords at lower elongation and two wefts;

Why has ELEMET LE been developed and introduced in the market?

New applications rising in the international market have made compulsory the development of different high-tech manufacturing technologies to meet more detailed customers’ requests.

With specific concerns on cement industry, it is possible to identify two main causes that have led to ELEMET LE development:

- Increasing height of silos heating towers, most of the times exceeding 100m, because problems connected to elongation. Therefore, it has been necessary to think of new, more resistant and flexible steel cords that can withstand such stress;

- Higher throughput of buckets which are loaded with bigger quantities and heavier materials than in the past to increase cement overall production.

Which are ELEMET LE main advantages?

The new carcass construction for steel cord elevator belts can be considered a more competitive, effective and efficient alternative if compared to traditional steel cord construction. This new item has been offering excellent performances meanwhile assuring some crucial advantages such as:

- higher transversal stiffness given by the double weft to guarantee bolts support and function stability;

- a resistant structure thanks to longitudinal steel cord wires with reduced diameter to obtain low elongation, easy alignment and high flexibility in bending for better joint performance;

- brassed wires to ensure long-lasting rubber adhesion;

- special polymers used for rubber covers to maximize temperature resistance on long-term;

- breaking load from 800 to 3500 KN/M and widths suitable for all exhigences, from 300 to over 1600 mm;

- optimized covers thicknesses to ensure the best compromise between carcass protection, wear and long-lasting bolts tightening.

Referring to all these above-mentioned advantages, it is easy to understand why ELEMET LE has rapidly been gaining end users’ confidence in the international market. As a matter of fact, once installed, this new steel cord elevator belt has offered a clearly increased useful lifetime.

SIG experience in the Indian market

As far as SIG's experience in the cement industry is concerned, India has always represented one of the biggest and most important markets worldwide, with an average annual production of 360 million tons.

This enormous output has not only justified significant commercial and technical investments over the years but has also led to close cooperation with rubber conveyor belt distributors in India, who play a key role in supporting the country's massive material handling needs.

Strategic Partnership with Local Manufacturers: collaboration with Chanderpur

Once understood this great potentiality, the second crucial step has been about finding a local reliable partner that could represent and distribute SIG steel cord elevator belts in India so to penetrate the market.

For this reason, for many years, SIG established a strategic partnership with Chanderpur, a local OEM with a great reputation on the market.

Established in 1962, the company has grown a lot, becoming a multi-sectorial engineering society with activities in many different industrial fields such as biomass power plants, cement plants, fertilizers and mines, providing their customers with new spare parts supply but also engineering, installation and maintenance services as well.

Despite the fact of having different activities, it is possible to state that cement industry is one of their main strengths. Chanderpur offers their customers complete solutions:

- on-site consultancy to engineering service

- belts distribution

- installation or maintenance of conveyor belts

All of that depending on customers’ specific requirements.

Nowadays, Chanderpur is SIG official distributor for steel cord elevator belts in the Indian sub-continent: a fruitful cooperation for both involved parties assuring mutual satisfaction.

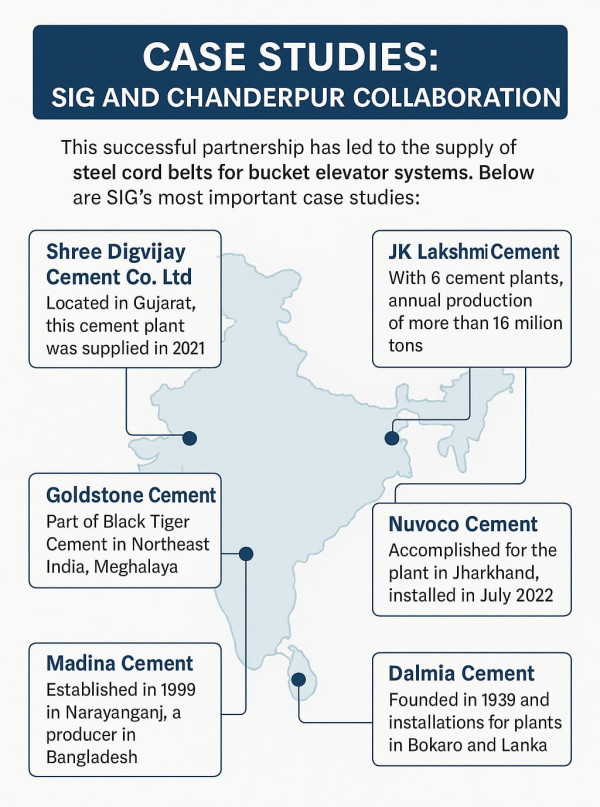

Case Studies: SIG and Chanderpur Collaboration

This successful partnership with Chanderpur has led to the supply of an incredible number of steel cord belts for buckets elevator systems, but to give evidence of what claimed up to this moment, you will be given some details concerning SIG most important case studies:

Shree Digvijay Cement Co. Ltd

Located in Gujarat region, with an experience of more than 75 years, this cement plant was supplied in 2021 a 150m long ELEMET LE, with a breaking load of 2000 N/mm, in a global width of 850mm – installed for kiln feed elevator, this belt is still performing with great success;

Goldstone Cement

Now part of Black Tiger Cement, one of the leading cement producers in Northeast India, Goldstone cement plant in Meghalaya region installed 132m of ELEMET LE, having a breaking load of 2000 N/mm, in a global width of 450mm, thanks to Chanderpur partnership – this high-tech item is still performing assuring excellent results, handling fly-ash;

Madina Cement

Established in 1999 in Narayangonj region, Madina cement company is one of the most important producers in Bangladesh, with a strong reputation in national and southeast markets. For cement mill application, Chanderpur succesfully installed an 80 meters long steel cord rubber elevator belt, 1050mm wide; moreover, the belt was an ELEMET LE, so a low elongation high-tech steel cord belt with a breaking load of 2250 N/mm – this special and technologically advanced item is still performing assuring great results;

JK Lakshmi Cement

With more than 40 years of experience in the cement industry, 6 active cement plants and an annual production of more than 16 milion of tons, JK Lakshmi cement is for sure one of the most important players in the Indian market. Since December 2021, a traditional ELEMET with a breaking load of 1600 N/mm, in a width of 550mm and in a length of 90m – conveying fly-ash, this belt has been assuring customer full satisfaction;

Nuvoco Cement

Another great reference is represented by the supply accomplished for Nuvoco Cement Plant in Jharkhand region. Installed in July 2022 for packing plant operations, a traditional steel cord belt ELEMET with a breaking load of 1250 N/mm, 680mm wide and 63m long is still functioning meeting customer’s expectations;

Dalmia Cement

Founded in 1939, this company is among the most important and reliable player in the cement industry in India. Through Chanderpur, SIG has supplied many different steel cord elevator belts to various cement plants belonging to this group. In particular, two specific study-cases are highly relevant to understand the importance of such a partnership.

In 2022, Dalmia Cement plant based in Bokaro, for fly-ash handling, SIG supplied a traditional ELEMET 91m long, 450mm wide, with a breaking load of 1250 N/mm – this still belt is still running offering great results.

Still, in 2022, to another cement plant belonging to the same group, this time in Lanka, SIG delivered 85m of ELEMET LE (high-tech item), in a global width of 850mm, breaking load of 2250 N/mm – installed for mill application, the belt has been working satisfactory.

SIG’s Advanced Solutions for the Cement Industry

Cement industry has always been SIG most important industrial field for its worldwide supplies, providing end users with a wide range of products matching the strictest technical requirements.

Over the years, to match cement plants’ new exigences rising, SIG technical department has done incredible research and development work to design and manufacture new products satisfying these needs.

ELEMET LE surely goes in this way: a special brassed steel carcass composed by one warp and two double wefts of low elongation wires. Time by time, this high-tech construction has been able to gain the confidence of most of the cement producers worldwide, being installed in all kind of strong applications.

If you are looking for a reliable partner in the rubber conveyor belts industry for special and technologically advanced products such as steel cord belts for buckets elevator systems, please, get in touch.

Latest news:

CONTACT US

Discover more about our products

Would you like to have more information about our items?

Fill in the contact form and send your inquiry. One of our experts will get in touch with you as soon as possible.