Cement plant conveyor belt: typologies and rubber compounds applications

Types of conveyor belts

The cement industry is probably the industrial field where SIG belts are mostly supplied and installed, always meeting customers’ expectations and matching all necessary technical requirements. This aspect mainly depends on SIG wide range of products for cement industry applications and a large number of available rubber compounds as well. Thanks to these two just-mentioned characteristics, SIG rubber conveyors and rubber elevator belts can be installed to face almost any ending use inside a cement plant.

What kind of rubber conveyor belts are used in the cement industry?

If you deal with SIG range of rubber conveyors and rubber elevator belts, you can easily state that depending on conveyed material characteristics and conveyor system design, perhaps any item can be a reliable solution for cement industry applications.

Hopefully, during the years, SIG technical department has been able to study and consequently develop an incredible number of new rubber conveyor belt types, differing from others for carcass composition and construction, so becoming a kind of customized solution for a specific application. Consequently, to be ready to face all international market requirements, also rubber compounds have been subjected to an important improvement, setting up new options that could perfectly represent the most suitable solution according to the concerned application.

As claimed at the very beginning of this paragraph, perhaps any belt belonging to SIG range of products can perform with excellent results in the cement industry. Therefore, below you will find a brief, but detailed explanation of which kind of SIG rubber conveyor belt can be installed to execute a specific task.

TEXTER Rubber Conveyor Belts

TEXTER are EP carcass belts that can be used to convey clinker or limestone (just to quote some of them) from the quarry to the cement plant or inside the industrial plant before entering the productive process.

This item can be manufactured with an abrasion or a heat resistance rubber compound depending on the application's technical requirements.

SIDERFLEX - Steel cord belt

SIDERFLEX is SIG steel cord belt that is manufactured relying on high-resistance steel cables both in warp and in the weft as well. If compared to TEXTER, this belt has a far more increased resistance against cut, impact, and material tearings as well as guaranteeing an extremely reduced permanent elongation.

For this reason, this belt is normally used to cover long conveying distances (where EP belts could suffer from serious problems connected to elongation) or to handle heavy and sharp bulk materials, so avoiding any potential belt rupture that may cause serious problems to the productive process. In this case, also, it is also possible to equip SIDERFLEX with abrasion or heat-resistance rubber compounds.

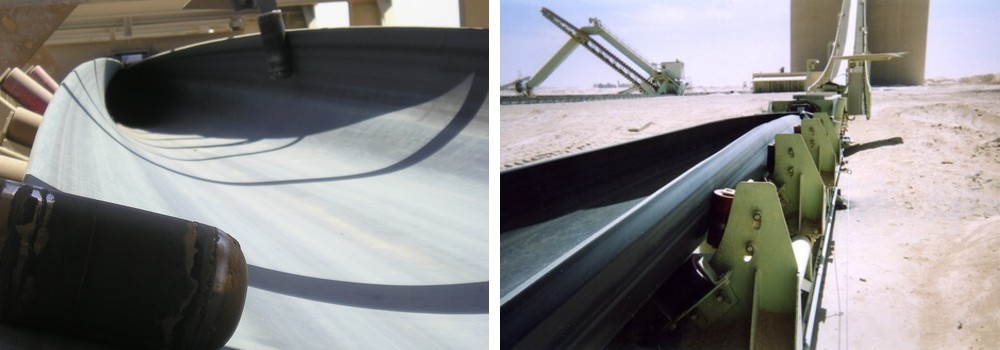

PIPE - Tabular shape rubber conveyor

PIPE is SIG tubular shape rubber conveyor belt that is used to handle bulk material avoiding dust or (more importantly) material spillage, thus standing for an environmentally friendly solution as it does not pollute the surrounding environment, especially if the cement plant is near public buildings or residential areas.

This high-tech item can be manufactured with a textile (EP) or a steel carcass according to the concerned industrial application-specific requirements, keeping the same characteristics of both carcass types as above described.

ELEMET - Steel cord belt

ELEMET is SIG steel cord belt, an indisputable technologically advanced product that has been designed (and improved as well during the years) to become the most suitable solution for cement vertical conveying inside heating towers. As suggested by its name, this belt is installed inside special heating towers where specific buckets are fixed on elevator belts' top cover to properly charge and convey cement in a vertical way (elevation).

Over the years, to face the increasing height of these towers and prevent steel cord elevator belts from suffering elongation problems, SIG technical department has been able to design and develop a new item, called ELEMET LE which is characterized by lower elongation if compared to standard ELEMET. Since these belts handle hot cement, they are always equipped with a heat-resistance rubber compound.

ELETEX - EP Carcass elevator belt

ELETEX stands for SIG EP carcass elevator belt which is not used inside cement plants heating towers due to high temperatures it could be exposed to and that it may not withstand. On the contrary, even if this item is not often installed in cement factories, it may be used for clinker or limestone vertical handling for specific storage silos. EP carcass elevator belts can be manufactured both with abrasion and heat resistance (at lower temperatures than ELEMET) rubber compound.

RIPSAVE & TEXBIND

RIPSAVE & TEXBIND are not used that often for cement industry applications being a more suitable solution for bulk goods conveying inside mines & quarries. Nevertheless, it may happen that to handle big size, heavy, and sharp material as well it could be necessary to rely on reinforced textile carcass solutions as in the case of RIPSAVE (having a transversal breaker in the top cover).

These two rubber conveyor belts can be equipped with abrasion and heat-resistance rubber compounds as well.

To summarise, what you have just read about is nothing but a detailed description of all different cement industry industrial applications that can be perfectly faced and executed by SIG wide range of rubber conveyors and elevator belts.

Nonetheless, for a better understanding of this specific industrial field's functioning, it is also necessary to deepen the topic concerning rubber compounds.

What rubber compounds can be used in cement plants?

Abrasion and heat-resistance rubber compounds are the ones mainly used in the cement industry, notwithstanding, there could be some exceptions.

SIG abrasion resistance rubber compounds

The abrasion resistance can be developed in three different options:

- CL: standard abrasion resistant” (compliant with Y degree of DIN 22102 standards) guaranteeing an abrasion loss equal or inferior to 150mm3;

- EC: extra abrasion resistant” (matching with W degree) having an abrasion loss which is always inferior to 90mm; 3)

- AS: superior abrasion resistant” option having a loss which is less than 50mm3 but not used very much for these applications.

SIG heat resistance rubber compounds

Heat-resistance rubber compounds are available in three different options:

- CX: standard heat-resistant rubber compound withstanding a maximum continuous working temperature of 130°C with peaks up to 150°C;

- MX: assures resistance to a continuous working temperature of 150°C with peaks up to 180°C;

- TX: maximum heat-resistant rubber compound guaranteeing the chance to handle material up to a maximum continuous temperature of 200°C, with peaks up to 300°C. This just-mentioned rubber compound is extremely particular as it can be equipped only on EP belts, but not on steel carcass ones as the specific rubber polymer used to produce such a rubber compound does not guarantee a perfect chemical matching with steel cables;

All these just analyzed rubber compounds can only be used for flat rubber conveyor belts, therefore they can be equipped on PIFLEX & PIPEX, RIPSAVE, SIDERFLEX, TEXBIND, and TEXTER, but they cannot be equipped on rubber elevator belts (does not matter if textile or steel carcass).

Referring to abrasion and heat resistance rubber compounds for ELETEX and ELEMET, you only have to consider what following:

- AX is SIG nomenclature to identify standard “abrasion resistance covers” (Y degree) that are used to equip only textile carcass elevator belt covers, but not steel cord ones. This option can also guarantee the withstanding of a maximum working temperature of 150°C;

- SX is used to identify heat resistance rubber compound for steel cord rubber elevator belts, guaranteeing the withstanding of a maximum working temperature of 100°C;

- BX is the “common” heat-resistant rubber compound, up to a maximum working temperature of 180°C, which is used both for EP carcass elevator belts and steel carcass ones.

Now, you have been given all the necessary technical data concerning SIG most used rubber compounds for cement industrial applications.

Notwithstanding, as claimed before making this brief description, there could also be some exceptions where it becomes necessary to rely on different options rather than abrasion or heat resistance.

SIG oil-resistant or self-extinguish rubber compounds

Sometimes inside cement plants specific conveyor systems are installed to handle industrial waste (as a partial result of industrial processes) or raw materials that are crucial to produce energy for the entire plant (such as coal that is later transformed into electric or thermal power).

In such situations, oil-resistant (for industrial waste handling) or self-extinguish (for coal conveying) rubber compounds may be necessary to perfectly execute this task:

- OM is SIG standard oil-resistant rubber compound, matching with G degree of DIN 22102 standards;

- AG can be considered an improved version as it is both oil-resistant and self-extinguish;

- BS is SIG nomenclature used to identify self-extinguish rubber compounds, compliant with DIN 22102 standards K degree.

To summarise, you have now been given all the information concerning SIG wide range of products and rubber compounds that can be used for cement industrial applications.

It is possible to claim that during the years, thanks to SIG technical department's fantastic work, SIG has been able to establish its brand as a benchmark in this industrial field since its products are worldwide recognized as a synonym of reliability and excellent quality.

If you are looking for high-tech rubber conveyor belts for the cement industry, please, do not hesitate to contact us at this email address: sig@sig.it

Latest news:

CONTACT US

Discover more about our products

Would you like to have more information about our items?

Fill in the contact form and send your inquiry. One of our experts will get in touch with you as soon as possible.