Rubber Conveyor Belt: materials and production

What is conveyor belt material?

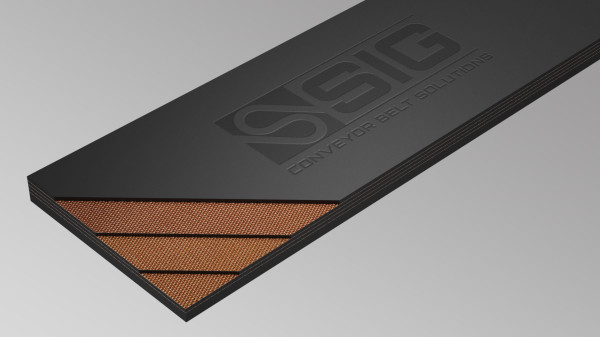

SIG rubber conveyor belts can be divided into two main categories: EP carcass and steel cord. They are all manufactured using special rubber layers to guarantee perfect adhesion between inner plies or steel cables and external covers and inside belt structures.

Outside specific rubber compounds with different chemical properties are equipped on bottom and top covers to give the item the necessary matching characteristics with the concerned industrial application. To give a clear example of what is just claimed, SIG can manufacture belts produced with abrasion or heat-resistant and self-extinguishing rubber compounds, depending on the conveyed materials' chemical composition.

What are the differences between EP Carcass and Steel Cord?

EP carcass rubber conveyor belts are mainly known as textile carcass ones.

Concerning the first mentioned ones, any belt belonging to this group is composed of at least two EP layers, any of which is manufactured with nylon fibers in the weft and polyester ones in the warp, assuring required mechanical properties such as tensile strength and elongation.

EP belts (textile carcass ones) are normally recognized for their great flexibility, low permanent elongation, and excellent adhesion between plies. They can be transversally used in many different industrial fields as they easily adapt themselves to multiple situations and their inner structure can be equipped with any rubber compound that has been developed by SIG technical department.

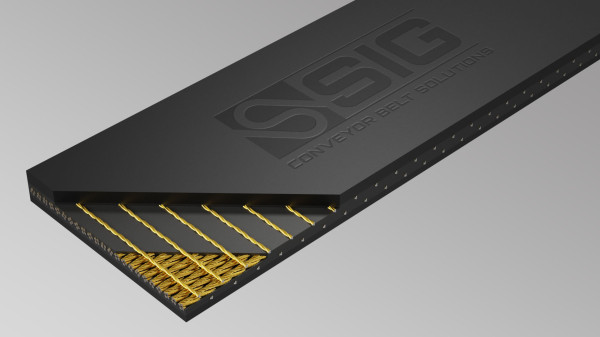

Steel carcass ones composed of brassed steel cables.

The second group concerns all belts manufactured with a steel carcass, that is to say, an inner carcass that is only composed of steel cables, guaranteeing the item other mechanical characteristics if compared to EP belts, such as a far reduced elongation and an increased resistance against external material impact on belts’ top cover, just to quote some of them.

Textile carcass rubber conveyor belts can suffer from two main situations:

- Big size, heavy, and sharp material falling on the belt top cover may cause serious cuts and tearings, making it necessary to replace the belt;

- Elongation problems connected to long conveying distances, usually more than 500m;

When facing such situations, it becomes necessary to refer to the second category mentioned at the beginning of the previous paragraph, that is to say, steel carcass rubber conveyor belts. These last ones are composed of only brassed steel cables that can assure a far increased resistance against external material impact, meanwhile guaranteeing a minimized elongation even when handling goods for distances exceeding 500m.

A remarkable aspect to be underlined is the fact that steel cord rubber conveyor belts can be manufactured according to three different carcass construction options depending on specific technical requirements concerning conveyor system design and industrial application.

Technical Analysis of SIDERFLEX Belt Carcass Types: ID, IW, and HE

Talking in detail, it is possible to identify the following carcasses:

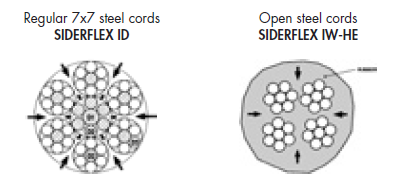

- SIDERFLEX ID / HD HD designed and developed relying on a 7x7 cables construction (identified as closed) with only one weft in the first case (ID) and two in the second one (HD).

- SIDERFLEX IW / HEmanufactured using a 4x7 cables construction (named open) having one weft in the first case (IW) whereas two in the second one (HE).

Of course, between ID, IW & HE construction there are some specific technical differences that need to be analysed and explained to have a better understanding of the topic.

Here below, you can find a brief summary:

- IW: warp is provided of open type cords (4x7) with increased elongation, and they have a longitudinal elasticity which is bigger than standard steel cord belts. On the countrary, weft is placed only in the upper side of the carcass, becoming suitable for troughing thanks to high transversal flexibility.

- ID: similar to IW, that is to say, that weft is built in the same way, what differs is warp construction. As a matter of fact, in this case, open cord are not used to form warp which is composed of only regular cords (7x7)

- HE: even though warp is built in the same way as an IW belt, weft completely differs as it is formed by two layers of which are placed in the belt top cover, so to give the belt increased resistance as well as stability. This construction ensures reliability and stability when conveying material over long distances.

Which are the main parts of a rubber conveyor belt?

An industrial belt comprises several structural components, with precise functions and technical properties tailored for specific industrial applications:

- Bottom Cover: made from a specialized rubber compound with particular chemical properties to ensure abrasion resistance and durability. Although it does not directly handle materials, it must have a minimum thickness of 1.5 mm to resist wear from dust, spillage, or blockage between rollers.

- Adhesion Rubber: A critical layer that ensures perfect bonding between the external covers and the internal carcass (textile or steel cord). Its unique chemical composition prevents ruptures or delamination, even under high tension.

- Carcass: This can be either a textile or steel cord, depending on technical requirements. Textile carcasses are made from nylon and polyester, with 2-6 plies based on customer needs. Steel cord carcasses may vary in construction but always include adhesion rubber to ensure a strong bond between components.

- Top Cover: The top layer handles direct contact with bulk materials and is designed for impact and tear resistance. Its thickness and rubber compound are tailored to the material being transported, such as heat-resistant compounds, to ensure long-term performance and avoid damage.

These components work together to ensure the belt's durability, reliability, and adaptability to various industrial demands.

What is the standard for a rubber conveyor belt?

Normally, in the rubber conveyor belt industry, you can identify what is perhaps known as the most common and standard construction that can be suitable for many basic industrial applications, even if handling different bulk goods, therefore transversal to an incredible number of fields.

What you have just been told can be identified as follows: "TEXTER 400/3 4+2 CL 800mm".

- TEXTER: which means this belt is a textile carcass one (EP);

- 400:N/mm stands for belt-breaking load;

- 3: which identifies plies number made of layers of nylon weft and polyester warp;

- 4: top cover thickness;

- 2: bottom cover thickness;

- CL: SIG nomenclature used to identify the used rubber compound, in this case, equivalent to Y degree of DIN 22102 laws (therefore standard abrasion resistant) that can be used in many fields;

- 800mm: indicates belt width, normally, for such a rubber conveyor belt, 800mm and 1000mm are the most common ones.

Which rubber compounds can be used to produce SIG rubber conveyor belts?

Talking about manufacturing chances, also rubber compounds display a key role in the manufacturing process: as a matter of fact, according to the specific handled material and to the concerned field, any industrial application needs to match with specific requirements in terms of abrasion or heat resistance for instance.

Therefore, SIG can manufacture rubber conveyor belts in abrasion, flame, heat, or oil resistance rubber compounds, always matching with what you are looking for.

Are SIG rubber conveyor belts suitable for mining handling?

SIG rubber conveyor belts are extremely suitable for mining handling: its wide range of products can offer many options, varying from textile belts to steel cord ones. Moreover, any of these items can be manufactured with various quality rubber compounds suitable for specific applications.

How is splicing carried out on SIG rubber conveyor belts?

Do you need useful information on how to splice rubber conveyor belts? You can find all the useful information in the here enclosed installation manuals. All these documents documents are specific for a different rubber conveyor belt category.

Do not waste precious time and get in touch at sig@sig.it to ask for a quotation or to simply get SIG technical department support to study the most suitable rubber conveyor belt for your needs.

Latest news:

CONTACT US

Discover more about our products

Would you like to have more information about our items?

Fill in the contact form and send your inquiry. One of our experts will get in touch with you as soon as possible.