Fire resistant rubber conveyor belts: what they are, which tests they are submitted to and their application

K degree of DIN 22102 standards main feature is guaranteeing that once the flame source is removed from the conveyor belt itself, the flame smothers in a very short time.

Belts manufactured using such a self-extinguish rubber compound can only be installed inside closed areas (such as grain storage silos) or other industrial above-ground installations where there can be a fire risk. If dealing with an underground application (such as a quarry or a mine for instance), respecting DIN 22102 standards K degree is not enough since belts must have anti-propagation properties.

Are there any specific tests for self-extinguish conveyor belts?

Self-extinguish rubber conveyor belts have to display a crucial function as they have to guarantee workers’ safety during potentially dangerous industrial processes.

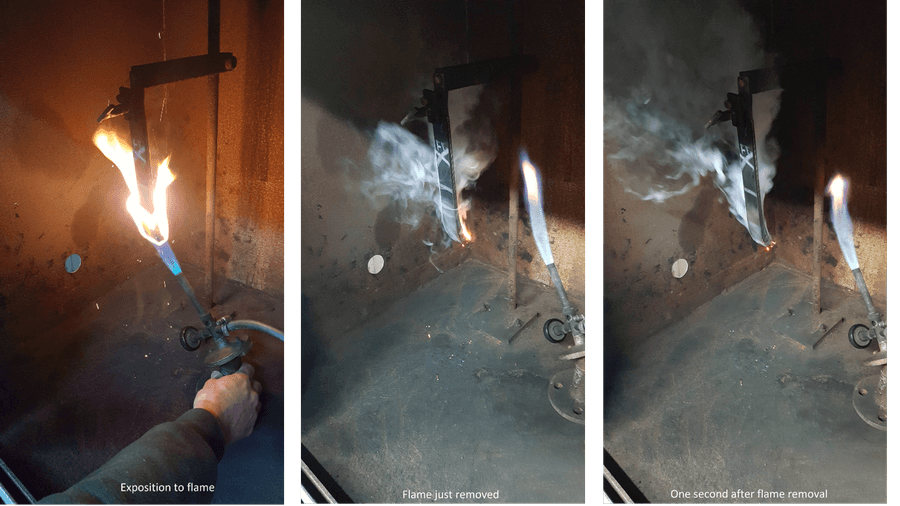

Therefore, to supply customers with reliable products matching these strict and specific requirements, SIG weekly submits its self-extinguish rubber conveyor belts to painstaking quality check tests. As claimed, the main feature of such an item is guaranteeing that once the flame source is removed from the conveyor belt itself, the flame smothers in a very short time.

Consequently, the lab test has to be carried out and conducted as follows: a series of six samples extracted from the rubber conveyor belt is subject to a 1,000°C propane burner flame for 45 seconds.

At the end of this period, the flame is removed and the necessary time for flame extinction is measured. The test can show a positive result and then the conveyor belt is classified as self-extinguishing when:

- the flame extinction time for six samples results in no more than 45 seconds;

- the time needed to extinguish a single sample flame cannot exceed 15 seconds;

- subjected to the air stream, the samples must not show any new flame formation.

After completing a test like the one just described above, if all results are positive as required, a belt can be considered 100% self-extinguish.

Which are SIG self-extinguishing rubber compounds, and when can they be used?

Inside SIG wide range of rubber compounds, you can identify two specific options for above-ground and/or closed-area industrial applications, preventing any potential risk connected to fire propagation.

BS RUBBER QUALITY

The first one you will deal with is BS compound: it has been projected and realised to be used for above ground and closed areas applications where safety is fundamental and fire risk is high. It is highly recommended for coal and potash applications. It is self-extinguishing according to ISO 340 and anti-static as per ISO 284 (equivalent to K degree of DIN 22102 standards).

AG RUBBER QUALITY

AG is a nitrile rubber compound that can commonly be considered an upgraded version of the previously analyzed one as it is both self-extinguish and oil-resistant, therefore standing for the most suitable solution for any application where it is also necessary to guarantee excellent protection from potentially handled materials’ oil loss.

Following international market-specific requirements, SIG technical department has been able to think of a new rubber compound that could be used for any special industrial application where DIN 22102 standards K (self-extinguish) and G (oil resistant) degrees have to be respected.

Normally, fertilizers and grain handling inside closed areas or above-ground conveying systems with potential fire risk are just two examples where this rubber compound becomes compulsory.

According to SIG “on field experience” AG rubber compound assures and gives its best performances when equipped on ELETEX and TEXTER while handling grain or in general, when installed inside agro-industrial plants in general. Just read the below study-cases dealing with a French engineering company to have clear evidence of what just claimed.

To summarise, AG cover rubber provides superior resistances to vegetable oils and animal fats meanwhile being self-extinguished and antistatic according to ISO 340 and ISO 284 to guarantee high safety to the conveyor plant.

Grain storage silos and port terminals for ship loading and unloading operations are the industrial fields where the AG rubber compound is mainly used.

SIG's Case Studies for AG & BS rubber compounds in 2022-2023

Up to this moment, you have been given many technical details about SIG BS and AG rubber compound, also having the chance to learn useful information about the test through which it is possible to check the self-extinguish feature.

Now, SIG's reference list will be a valid ally to make you learn about some iconic accomplished supplies of AG and BS rubber compound belts to give you concrete evidence of what claimed up to this moment.

Fertilizers port terminal Project: EP belt with fire-resistant rubber covers

In 2022, a French engineering company was in charge of completing fertilizers terminal for ship loading and unloading operations for an Asian seaport authority.

Since one of the handled material’s features was its flammable dust, from the very beginning it was clear that supplied goods would necessarily be self-extinguish and antistatic to minimize any safety risk for workers connected to a potential fire ignition and propagation.

Consequently, when the OEM company contacted SIG for this project, the choice over which type of rubber conveyor belt to be supplied immediately went on EP carcass rubber conveyor belt, equipped with BS rubber compound.

Thanks to SIG technical department's useful suggestions, the following constructions were agreed upon: more than 3km of EP belt, 1200mm wide, with 6mm on the top cover and 2mm on the bottom one, equipped with self-extinguish and antistatic rubber covers (matching with K degree) and with a breaking load of 630 N/mm, composed of 4 plies.

Plant installation and commissioning ended in December 2023.

Nowadays, both the French engineering company that delivered the whole conveyor system and the ending customer (seaport authority) are fully satisfied with the rubber conveyor belt performances, loading and unloading fertilizers from January 2024.

Bulk agro-industrial port terminal Project: ELETEX oil-resistant and self-extinguish rubber compound

This second study case will deal with an important project completed by SIG between 2022 and 2023 for the world’s most important bulk agro-industrial terminal located in the Far East.

The reason why ending customers needed an oil-resistant & self-extinguish and antistatic rubber conveyor belt was due to the fact that grain was handled material, and it had to be transferred from storage silos to proper ships through specific loaders. For all the above-mentioned reasons (closed area, flammable material dust…) any supplied rubber conveyor belt had to be manufactured with special rubber covers that could guarantee workers’ safety at any time. Talking in detail, the ending customer was provided with the following products:

- Many kilometers of EP500/3 and EP400/3, all equipped with AG rubber compound, manufactured with 3mm on top cover and 2mm on the bottom one, in various widths from 500mm, to 800mm and 1000mm.

- Moreover, to give ending customers suitable products as well to be inside silos, SIG also supplied different EP carcass rubber elevator belts, named ELETEX. These items were manufactured with a breaking load of 1000 N/mm, 5 plies to compose the inner carcass, equipped with 3mm on top as well on bottom covers which had been produced oil-resistant & self-extinguish and antistatic rubber compound.

Are there any other specific flame-resistant rubber compounds inside SIG range of products?

At the moment, you have had the chance to deal with self-extinguish rubber compounds for above ground applications, nevertheless, in the rubber conveyor belts industry it may happen that some activities have to be carried out inside underground areas or tunnels as well.

Specific standards norming industrial activities with risk of a potential fire propagation mention that for any undeground installation rubber conveyor belts must be equipped with a special rubber compound that prevents the item from being a source of fire. In this case, the main principle is not only smothering the flame in a very short time, but to avoid fire propagation.

When facing such an application, standard self-extinguish rubber belts at the ones recently described cannot be used since they could not match the strict safety requirements that are required and necessary for undeground applications.

As a matter of fact, any belt that may be installed inside an underground application must not be an active fire spreader, so a different concept if compared to self-extinguish as in the first mentioned cases, as in this case the belt must avoid any potential fire propagation.

TS RUBBER QUALITY

TS is produced with a specific rubber compound that has been designed to service both underground and above ground applications. It is highly recommended for the belt conveyors located in the back areas of the tunnels. TS is designed according to DIN 22102 S grade, ISO 340 and ISO 284 or equivalent.

This is a special option as in this case, not only belt external covers, but also inner rubber, the one used to guarantee a better adhesion between plies and belt structure, must be self-extinguish. Therefore, the test to check the actual and real main feature is not only carried out on an external covers sample, but also on a piece of inner carcass.

TV RUBBER QUALITY

This technologically advanced option has been designed to work in underground applications where it is necessary that the belt does not trigger centres of fire. It is recommended for the belt conveyors located close to the permanent workstations in underground applications or tunnels. TV is designed according to ISO 340, ISO 284, EN 14973 or equivalent.

Dealing with TV rubber compound means that it is necessary to cope with two new different tests:

- friction test

- gallery test

The two just-mentioned tests can be carried out with different parameters and regulations to be matched, according to the level you are referring to.

To give you some more information about gallery test, a rubber conveyor belt sample (not only a small piece in the case of self-extinguish belts) is exposed to an active source of flame and placed inside a gallery (tunnel) where it subjected to a continuous air flow increasing fire action.

A positive result is shown when once this the heat source is removed and the flame becomes extinct, there is still a belt region completely undamaged. This experiment has to prove that when the flame source is withdrawn, the belt will not be an active fire spreader, preventing its propagation clearly leaving undamaged belt regions (that can have different sizes according to the test level you are referring to.)

Do not waste precious time and get in touch at sig@sig.it to ask for a quotation or to simply get SIG technical department support to study the most suitable rubber conveyor belt for your needs.

Latest news:

CONTACT US

Discover more about our products

Would you like to have more information about our items?

Fill in the contact form and send your inquiry. One of our experts will get in touch with you as soon as possible.