Chevron Conveyor Belts: Why are they developed? Features and application fields

What are Chevron Rubber Conveyor belts?

As the one and only Italian leading manufacturer of rubber conveyor belts, at any time SIG must be ready to satisfy all international market requirements and needs in terms of new products' development.

Therefore, inside SIG a wide range of items (including high-tech pipe conveyors and low elongation steel cord elevator belts just to quote some of them) you can also find chevron rubber conveyor belts.

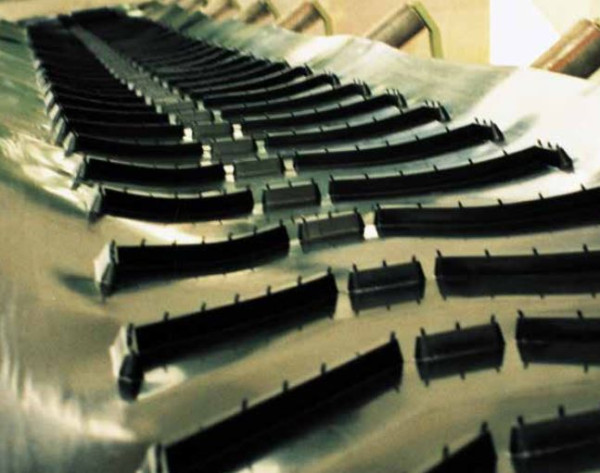

These last ones are textile carcass rubber conveyor belts (it is not possible to produce them with a steel cord construction) manufactured with special industrial molds that allow placing special cleats on belts’ top cover during production stage.

This just described method works as a kind of hot vulcanization since it makes stronger the bonding between cleats and belt top cover, increasing their resistance against external impacts and possible tearing’s caused by handled material. In this way, the cleats appear belonging to the body of the belt.

Why has Chevron Rubber Belt SPINATEX been developed?

Basically, SPINATEX has been developed and designed to be the most suitable solution when handling bulk materials or even bags when you must face an inclined conveying angle, usually less than 30 degrees because after this measurement, it becomes necessary to rely on a cleats and sidewall belt (named as FLEXOBORD).

As a matter of fact, it may happen that in some situations, bulk materials or bags must be conveyed in an inclined direction, making it necessary to think of a solution that could avoid their slippering and consequently their falling that may cause a flow rate loss.

Thus, over the years, SIG technical department has been studying a solution that could overcome such a problem: since inclination angle is lower than 30 degrees, cleats and lateral sidewalls have not been considered as lateral falls have not been seen as a serious problem. On the contrary, vertical falls due to material slippage must be tackled and from the beginning it has become clear that containing the material inside the pattern could be the one and only possible solution.

Chevron Surface Conveyor Belts: how many SPINATEX models are available?

Depending on the application and handled material as well, since the very beginning SIG has designed three different cleat patterns that can be used to manufacture chevrons belts, guaranteeing these items can have the most suitable shape according to conveyor system characteristics.

According to what has just been claimed, SIG range of chevron belts is composed of:

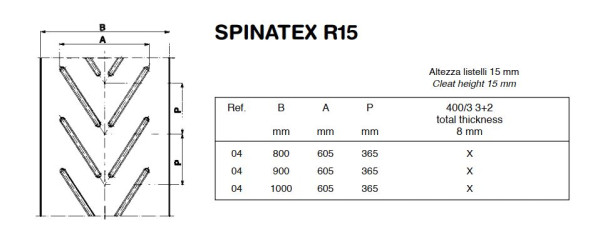

SPINATEX R15 Chevron Belt

It is the first model of chevron belt where cleats have a “V” shape with only vertical bars composing it, and they have an overall height of 15mm each.

This item can be manufactured only in widths of 800mm, 900mm and 1000mm, cleats pitch is about 365mm, and pattern width is 605mm.

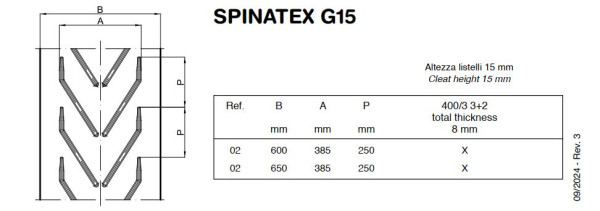

SPINATEX G15 Chevron Belt

It is the second model of chevrons belts and can be considered a kind of upgraded version of the above one. As a matter of fact, even if cleats height is still of 15mm, their shape is different because apart from two vertical bars composing the “V” shape, you can also identify two horizontal bars, vulcanized together with the two vertical ones.

This creates a wider area for material handling than observed before. In this case, belt width can vary from 600mm to 650mm only, cleats pitch is 250mm, but distance A is 385mm. On your right, you can observe a picture explaining what just claimed.

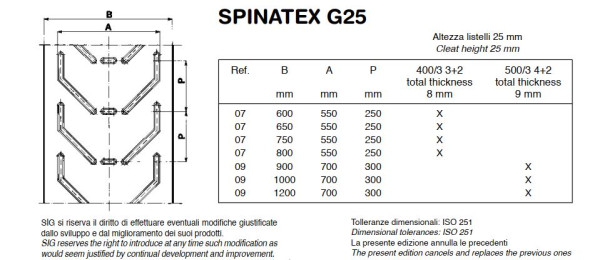

SPINATEX G25 Conveyor Belt

It is the third and last model of chevrons belts, it can be easily recognized for having an overall cleats height of 25mm, but also because of their shape. As a matter of fact, apart from the two horizontal and vertical bars composing the recurrent “V” shape, you can also identify a horizontal bar, separated from the two vertical ones, forming a kind of “closed” cleat.

Belt width goes from a minimum of 600m to a maximum of 1200mm, whereas cleats pitch can be 250mm for belt width up to 800mm, after this last one, it can reach 300mm. Last, but not least. The pattern width can be 550mm or 700mm according to belt width.

SIG SPINATEX Constructive Options: Carcass and Rubber Compound

As just explained, SIG range of EP carcass chevrons belts has three different manufacturing options in terms of cleats height and shape as well. Any of these mentioned “models” has a specific standard concerning breaking load, covers thickness and width.

Dealing with SPINATEX R15, this belt is standardized according to the following constructive option EP 400/3, with 3mm on top cover and 2mm on the bottom one. This specific item can be produced 800mm wide, 900mm wide or 1000 mm wide.

Very similar to the first model, the second one (SPINATEX G15) is standardized as EP 400/3 and top & bottom covers thickness equal to 3mm + 2mm Nevertheless, what really differs is belt width: as a matter of fact, in this case, only 600mm and 650mm are available widths.

Last, but not least, it is high time to talk about SPINATEX G25 which has been designed and conceived for the heaviest and the most demanding industrial applications. This belt can be manufactured according to two different standards:

- From 600mm to 800mm, SPINATEX G25 is standardized as EP 400/3 and with 3mm on top cover and 2mm on the bottom one;

- From wider belts (up to a maximum width of 1200mm) this special item is standardized as EP 500/3 4mm + 2mm.

All SPINATEX options can be manufactured relying on the following rubber quality:

- AG: fire-resistant (according to K degree of DIN 22102 standards) and oil resistant (according to G degree DIN 22102 standards);

- BS: fire-resistant (according to K degree of DIN 22102 standards);

- CL: standard abrasion resistant cover guaranteeing an abrasion loss equal or inferior to 150mm3 (equivalent to Y degree of DIN 22102 standards);

- CX: heat-resistant covers assuring the withstanding of a continuous working temperature of 130°C with peaks up to 150°C;

- EC: extra abrasion resistant cover guaranteeing an abrasion loss equal or inferior to 90mm3 (equivalent to Y degree of DIN 22102 standards);

- MX: heat-resistant covers assuring the withstanding of a continuous working temperature of 150°C with peaks up to 180°C;

- OM: oil resistant option matching DIN 22102 standards G degree. What is extremely important to be remarked on is that SIG chevron belts can only be produced with closed edges, no cut edges option can be accepted.

Application Areas and Availability of Chevron Belts

Which are the industrial applications where SPINATEX can be installed?

Up to this moment, we have successfully analyzed all different SPINATEX constructive options concerning cleats height and their shape, breaking load, top & bottom cover thickness as well as available rubber compounds.

This brief but detailed summary should let you allow to think about the different industrial fields where SPINATEX can stand for a reliable item.

Nonetheless, have you ever asked yourself which can be the industrial fields where SIG EP carcass chevrons belts can be installed?

According to our expertise in the rubber conveyor belts industry, SPINATEX can find a source of application, assuring very important results in:

- Batching plants to convey sand, small stones, limestone;

- Cement industry for loading trucks with cement bags;

- Recycling plants where chevrons belts are widely used to handle both industrial and urban waste to feed incinerators that can produce energy starting from this alternative fuel;

- Wood industry where SPINATEX are installed to accomplish a similar task as the one described before since sometimes, they convey recycled wood to produce energy whereas in some other occasion, they are used to handle this product after manufacturing process.

Chevron Conveyor Belt Manufacturers: SIG S.p.a.

You have now been given all the details concerning SIG range of EP carcass chevrons belts, named and commonly known as SPINATEX in the rubber conveyor belts industry. A special and high-tech item that is extremely useful for “special applications” where standard EP belts could not assure satisfying performances.

Do not waste time and get in touch with us:

- Email: sig@sig.it

- Phone: +39 0331 36 51 35

Latest news:

CONTACT US

Discover more about our products

Would you like to have more information about our items?

Fill in the contact form and send your inquiry. One of our experts will get in touch with you as soon as possible.