TEXBIND: an EpP carcass reinforced solution for heavy applications

Have you ever dealt with EpP carcass rubber conveyor belt before? If not, this will be a unique occasion to learn useful information about this special item!

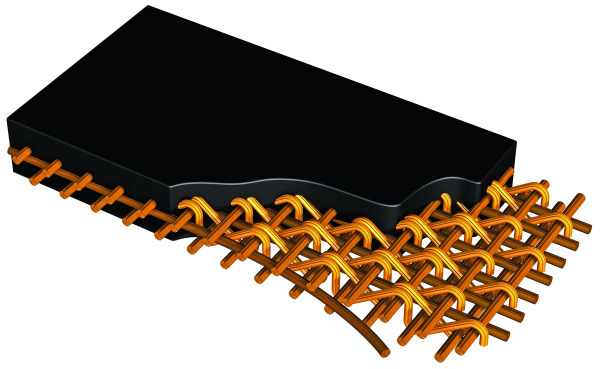

As you might have understood reading the title, TEXBIND are manufactured following a special carcass constructive option which is normally and usually identified as EpP. Differently from standard EP rubber conveyor belts, where a polyester warp is combined with a nylon weft, in this case, two nylon binders strengthen the belt's overall resistance against external material impact becoming a textile carcass-reinforced solution.

They are fully compatible with textile carcass multiply belts, so modifying existing plant designs will not be necessary.

How is TEXBIND manufactured?

These items have been designed to be a universal solution for mining applications where high resistance and maximum flexibility have always been required to face demanding industrial applications involving big-size and heavy bulk material handling. TEXBIND carcass construction is designed and developed according to the following characteristics:- Straight warp polyester yarns ensure low elongation combined with high tensile strength and superior longitudinal flexibility if compared to EP belts;

- Double layer of weft nylon yarns that assure high resistance against external material impact, cut, and tearing meanwhile guaranteeing good troughability. Furthermore, they are also responsible for a good connection with polyester warp assuring great belt stability.

What is the difference between MONO and DOUBLE ply construction?

MONO PLY CONSTRUCTION

Normally, TEXBIND is manufactured with only one ply that provides belt mechanical characteristics such as elongation, flexibility, resistance against impact, and troughability as well as.

Notwithstanding, when dealing with extreme industrial applications where high tensions on the textile carcass are involved and they are combined with big-size material falling on the belt top cover from considerable heights, a special version of the belt with two textile layers is available.

DOUBLE PLY CONSTRUCTION

The already increased resistance against impacts (if compared to standard EP belts) is now doubled not only because of the second carcass layer but especially thanks to the perfect synergy guaranteed by the intermediate rubber layer specifically designed to equally distribute impact energy on the doubled carcass. Nevertheless, mono-ply construction makes belt carcass thinner so deleting any possible ply separation.

To summarise what has just been claimed, double-ply TEXBIND is the most suitable solution for extremely demanding applications where a greater resistance against external material impact is required.

What are the main differences between TEXBIND and EP belts?

EP belts (normally identified as TEXTER according to SIG nomenclature) are multiply textile carcass rubber conveyor belts which means that they are composed of two or more layers of polyester warp and nylon weft. On the contrary, EpP weaving has been introduced to overcome TEXTER limitations in terms of higher elongation, lower weft resistance for heavy applications, and higher thickness with consequent belt stiffness.

Straight warp allows for reduced elongation meanwhile the double weft can assure an increased fabric resistance against external material impact or tear. Talking in detail, the most important advantages that TEXBIND can offer if compared to TEXTER are the following:

- An extremely high cutting, impact, and tear resistance thanks to a special double-reinforced weft.

- Superior longitudinal flexibility that allows using smaller pulleys.

- Very low permanent elongation assured by straight warp construction.

- High efficiency with mechanical jointing.

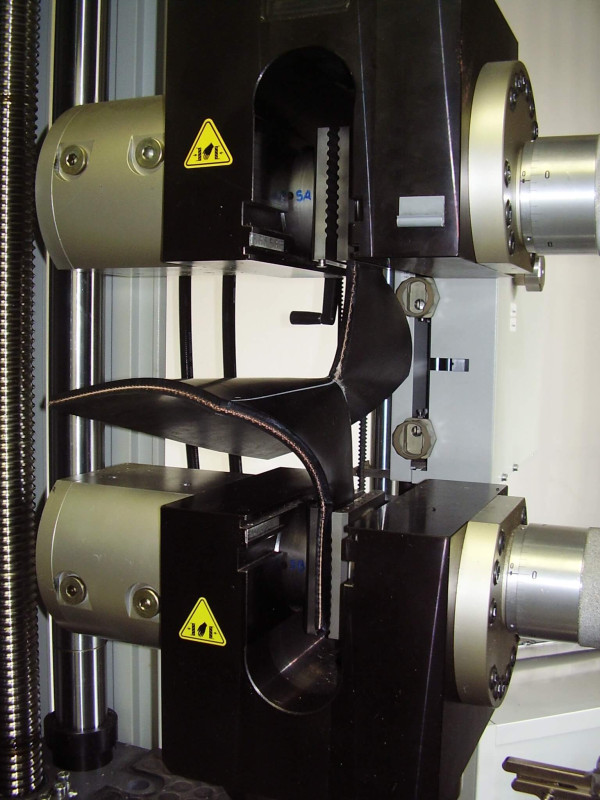

TEXBIND has always been designed and thought to stand for a textile carcass reinforced solution, so a TEXTER improvement for specific demanding handling applications. This feature can be observed when submitting a TEXBIND sample to some laboratory tests: during the analysis, you will observe that EpP carcass belt resistance against cut, impact, or tear will constantly increase without giving any sign of collapse.

This situation depends on TEXBIND weft yarns that are free to move inside straight warp fabric, getting closer to each other and improving belt cut, impact, and tear resistance. What has just been described cannot happen for EP belts where weft yarns tend to break singularly just because binded in the fabric woven structure.

What industrial application has TEXBIND been designed for?

TEXBIND has been designed and developed to be an important solution for the quarry and mining industry where it is necessary to supply products with an important resistance against cut, impact, and tear; notwithstanding, EpP carcass rubber conveyor belts can be transversally used for different industrial applications.

The only thing to be required is that the concerned application involves handling big-size or heavy materials that can seriously damage the top cover and internal carcass due to their shape.

Therefore, in the years, SIG has successfully supplied TEXBIND to different industrial plants such as cement plant, recycling plants and steel making industries just to quote some of them, always managing to meet and satisfy customer’s expectations. According to what just stated, TEXBIND can be manufactured using the following rubber compound:

- Abrasion-resistant, which is available in standard, superior, or extra options matching different International Standards

- Flame resistant

- Heat resistant, making a distinction between medium and high resistance according to different temperatures

- Oil resistant

Throughout the years, SIG has been able to improve TEXBIND's manufacturing process, supplying its worldwide customers with a unique product that has always matched their expectations. A great sign of indisputable top quality characterizing the SIG manufacturing process has been its ability to satisfy any requests in terms of different rubber quality, cover thickness, and width.

Therefore, if you are looking for a reliable partner in the rubber conveyor belt industry for such an important item, please, get in touch at sig@sig.it and do not lose precious time.

Latest news:

CONTACT US

Discover more about our products

Would you like to have more information about our items?

Fill in the contact form and send your inquiry. One of our experts will get in touch with you as soon as possible.