The use of Sidewall Conveyor Belt and its applications

What is a sidewall conveyor belt?

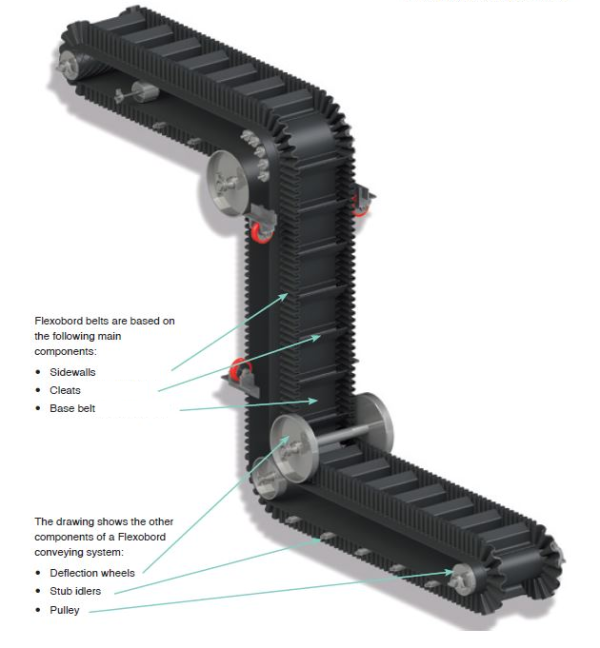

When dealing with bulk handling equipment, you should have heard about sidewall rubber conveyor belts: specific high-tech items that prove to be suitable for industrial applications where the conveying angle is extremely steep.

When facing such a complex conveyor system, using standard conveyor belts may cause a potential material loss while handling operations, as the absence of cleats and lateral sidewalls could not prevent bulk material from falling due to huge inclinations.

Therefore, to prevent this situation from happening, over the years SIG technical department has studied, designed, and later developed a breakthrough solution that could overcome huge conveyor system inclinations that have proven to be harmful to proper handling operations.

This challenging and motivating R&D work has led to FLEXOBORD® development.

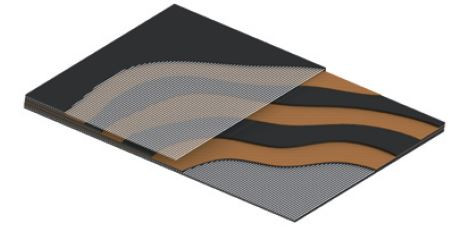

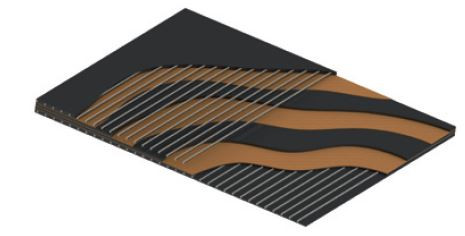

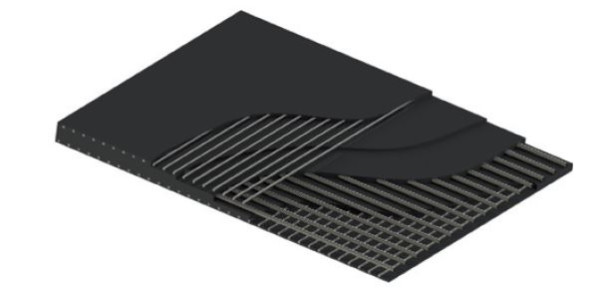

As you should have understood, FLEXOBORD® is a SIG rubber conveyor belt with sidewall and cleats that can be transversally used in many fields where inclined conveyor systems are required.

Due to its versatility, it has been necessary to think of different construction options so that this item could withstand different working conditions, while always guaranteeing safe goods handling as well as excellent performance. Therefore, when designing a FLEXOBORD®, the first aspect to be considered is its base belt construction, on which cleats and sidewalls would be later hot vulcanized.

What are sidewall conveyor belts designed for? And what are their parts?

Dealing with carcass construction, it is possible to identify three different constructive options that can be chosen depending on the conveyor system's characteristic:

XR CONSTRUCTION which is composed of only textile fabrics with high transversal stiffness, is provided by 2 additional special synthetic layers set in the cover rubber, assuring correct cross-stabilizing properties. Mainly known as TEXRIGID®.

| STANDARD TEXRIGID ® CONSTRUCTION | |||||

| BREAKING LOAD | 500/3+2 | 630/4+2 | 800/5+2 | 1000/5+2 | 1250/5+2 |

| TOP AND BOTTOM COVER THICKNESSES | 5+3 | 5+3 | 5+3 | 5+3 | 5+3 |

SR CONSTRUCTION is composed of multi-ply synthetic carcass and suitable steel reinforcement to ensure high transversal stiffness for heavy industrial applications. The main difference between this construction, known as CROSSRIGID ®, and the previous one is the presence of a steel transversal reinforcement in the belt top cover, named breaker

| STANDARD CROSSRIGID ® CONSTRUCTION | |||||

| BREAKING LOAD | 500/3 | 630/4 | 800/5 | 1000/5 | 1250/5 |

| TOP AND BOTTOM COVER THICKNESSES | 5+3 | 5+3 | 5+3 | 5+3 | 5+3 |

ST CONSTRUCTION stands for 100% steel carcass construction, and it is designed for the heaviest applications where conveying capacities are involved and required. Therefore, it is composed of steel longitudinal cords with special transversal steel reinforcement (breaker) to ensure the required stiffness.

This cross-stabilized construction is known as CROSSRIGID HR®. For this specific high-tech item carcass construction must be designed and selected on every single project due to its particular features CROSSRIGID HR®.

Another remarkable aspect to underline is that the base belt can be manufactured in abrasion-resistant, heat-resistant, flame-retardant, or oil-resistant rubber quality, depending on the concerned industrial application.

What are the types of corrugated wall conveyor belt sidewalls?

Cleats and sidewalls are the second crucial element that makes FLEXOBORD ® a special item in the conveyor belt industry. As a matter of fact, according to conveyor system characteristics and the handled material as well, it is possible to choose between four different cleat options in terms of shape, thickness, size, and width as well as.

Here below, you can observe a summary of cleats' different construction possibilities:

C type which is available in six different sizes

C type which is available in eight different sizes

N type which is available in three different sizes

C type which is available in nine different sizes

Of course, on special demand, supported by SIG technical department, it could be possible to study and verify if other cleats specific models can be developed.

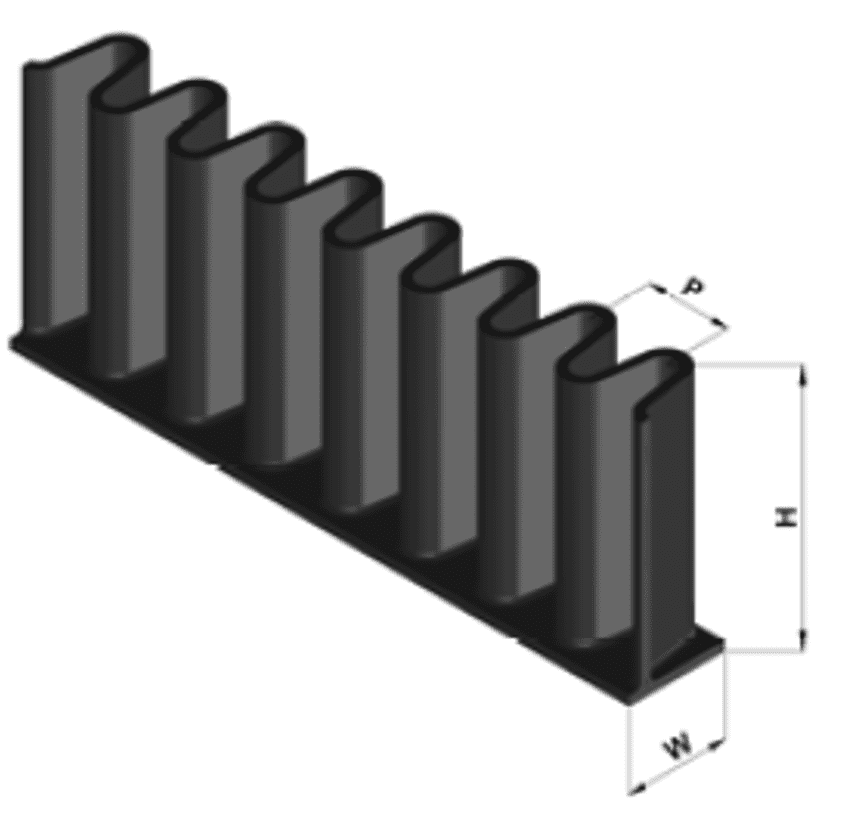

On the contrary, talking about sidewalls, they must be corrugated because thanks to their specific shape they have to guarantee belt elasticity when passing over deflection wheels, otherwise, not having the chance to “open as a fan” they would let edges be damaged by deflecting wheels causing belt tearings that could potentially lead to material lateral loss.

Sidewalls are always realized referring to three different crucial data which are: height (minimum 40mm up to a maximum of 630mm), width (minimum 30mm up to a maximum of 100mm), and pitch (starting from a value of 25mm and reaching a maximum of 83mm).

What are the advantages of corrugated sidewalls?

Once arrive at this stage, you should have all the necessary information to understand that FLEXOBORD ® is the conveyor belt used for material handling for inclined systems with an extremely steep inclination angle. This item has been specifically designed to overcome such a problem, guaranteeing some crucial advantages as:

- increased handling capacity

- absence of material spillage

- low power requirement

- minimized maintenance costs

What are the application areas where the sidewall conveyor belt is used?

As claimed at the very beginning of this article, FLEXOBORD ® can be transversally installed in many different conveyor systems, therefore performing in a wide range of industrial applications, such as:

- Batching plants

- Cement plants

- Foundries

- Mines

- Power plants

- Steel plants

- Tunneling

Latest news:

CONTACT US

Discover more about our products

Would you like to have more information about our items?

Fill in the contact form and send your inquiry. One of our experts will get in touch with you as soon as possible.