What are SIG Steel Cord Conveyor Belts?

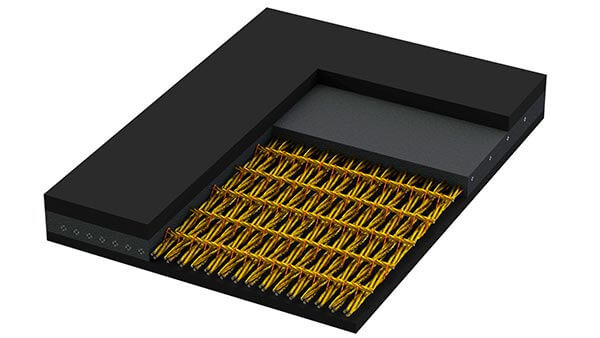

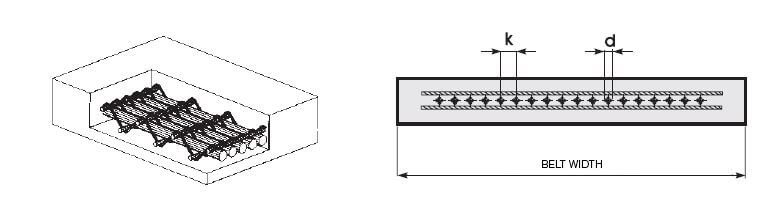

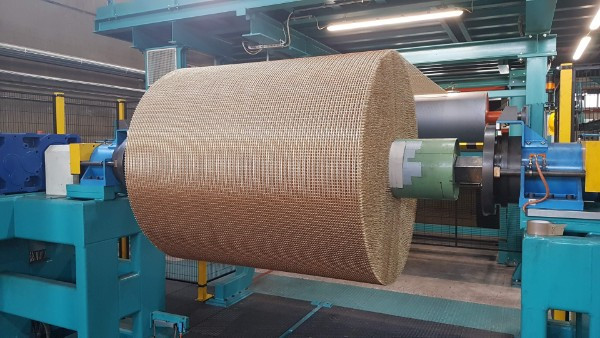

SIDERFLEX is SIG's name to identify its steel cord rubber conveyor belts: items manufactured with a 100% brass coated steel fabric (as shown in the 1st picture), characterized by low elongation which gives the belt a high tensile strength.

SIDERFLEX is not a simple steel cord belt, but a highly innovative product that has been specifically designed to overcome some recurrent problems connected to traditional steel cord conveyor belts. As a matter of fact, SIG technical department has been studying this new innovative product with our steel carcass supplier for many years, managing to set up a specific steel fabric construction.From traditional metal belts to steel cord conveyor belts

This steel fabric is the excellent result of two technologies connection: steel wires and weaving, an incredible illuminating insight that has helped to sort out recurrent problems connected to traditional steel cord belts.

In the past, although TST (traditional steel cord belts) belt had established themselves as a benchmark in the bulk material industry, many times they faced some recurrent problems which highlighted their weaknesses:

- Due to the presence of “foreign” sharp objects in the handled bulk mass, it could happen that the belt could be torn in two parts so becoming useless for its actual task;

- Furthermore, the high longitudinal stiffness of steel cords cannot easily bear high energy impacts caused by handled material falling onto the belt at the loading point.

The reason for these two main problems lies in the fact that TST is manufactured according to a mono-dimensional carcass construction where simple steel cables are placed along the main belt axis.

On the contrary, to overcome such problems as well as to propose a technologically advanced alternative to TST carcass construction, SIG was able to set up of high-quality steel cord belt equipped with a bi-dimensional form of protection granted by the presence of a double layer of steel cords which are placed on one or both sides of the warp structure.

What are the features and advantages of steel cord conveyor belts?

A carcass construction like the one just described does not only increase belt resistance against “foreign” object impact avoiding its tearing but also improves its longitudinal stiffness.

Have you ever asked yourself which are the main advantages given when relying on a SIDERFLEX belt?

- An excellent cut and tear resistance combined with a good impact resistance

- A high tensile strength united with low elongation

- A very good trough ability in addition to an extreme longitudinal flexibility

SIG SIDERFLEX can be designed and manufactured according to different constructions that match with specific technical requirements according to the concerned industrial application.

As a matter of fact, steel cord belts can be divided into three categories, which are

- SIDERFLEX ID

- SIDERFLEX IW

- SIDERFLEX HE

These different items vary for cord construction characteristics in terms of warp and weft.

Technical Specification of the SIDERFLEX product

Here below, you can find a brief summary of what just claimed:

WARP CONSTRUCTION

It deals with longitudinal steel cords construction, giving the belt elasticity as well as resistance characteristics, meanwhile defining its running properties.

When talking about SIDERFLEX IW and SIDERFLEH HE, these belts are provided with open-type warp cords with increased elongation so to have an increased longitudinal elasticity than the standard steel cord belts.

On the contrary, SIDERFLEX ID series is manufactured with regular warp cords, in order to have the same characteristics as traditional steel cord belts.

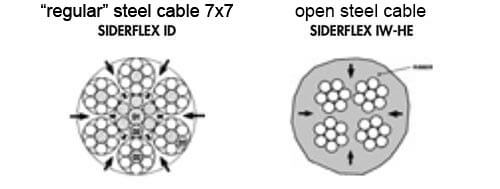

The picture gives a clear explanation of the main difference between SIDERFLEX ID and SIDERFLEX IW-HE as for warp construction: as a matter of fact, SIDERFLEX ID is manufactured using 7x7 cables (defined regular) construction, which is also known as “closed” construction. This depends on the fact that there is no available space between the 7 smaller cords (any of which contains the other 7 smaller filaments) composing the biggest one.

On the contrary, SIDERFLEX IW-HE is produced with an “open” carcass construction, known as 4x7, which means that any bigger cord is only composed of 4 smaller cords (but still with 7 smaller cords inside) instead of 7 as it happens in the SIDERFLEX IW-HE case.

According to what is explained here below, a 4x7 construction gives the belt increased longitudinal flexibility since the 4 inner cables have much more available space to move inside the bigger cord.

WEFT CONSTRUCTION

It concerns the whole set of transversal steel cables increasing the belt specific resistance against cuts, tears and impacts while also improving belt flexibility.

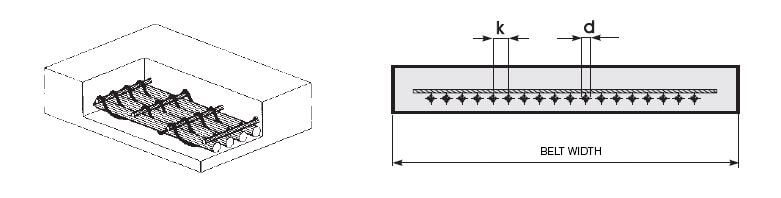

SIDERFLEX IW – ID fabric structures are built so that one weft layer is placed on the upper side of the carcass. Belts of these series are particularly suitable for troughing thanks to their high transversal flexibility.

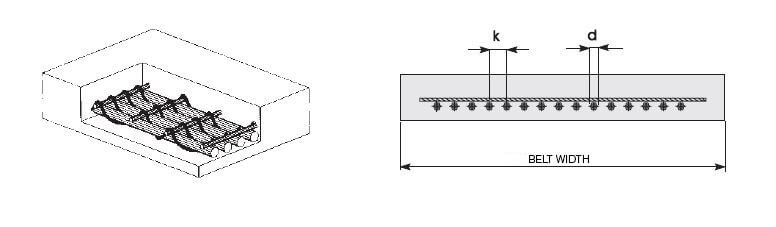

SIDERFLEX HE has manufactured ed with two different layers placed on both sides of the warp structure. The presence of a double weft gives the belt moderate transversal rigidity, anyway acceptable for the most common applications. HE series is highly recommended when exceptional values of cut and tear resistance are required.

Here below, you can observe three different tables that can explain to you all the different SIDERFLEX construction according to their technical peculiarities in terms of a carcass.

SIDERFLEX IW (SINGLE STEEL WEFT)

SIDERFLEX ID (SINGLE STEEL WEFT)

SIDERFLEX HE (DOUBLE STEEL WEFT)

Up to now, we have talked about technical aspects connected to different carcass construction options, but now it is time to focus on some specific properties conveyed by SIDERFLEX for the mechanic as well as chemical aspects.

As far as elongation at break is concerned, low elongation is one of the most important characteristics of steel cord belts.

Moreover, "creep" is the permanent elongation that the belt shows in the first period of life, and in comparison with textile carcass belts, SIDERFLEX can guarantee a very reduced "creep", generally negligible. This just mentioned is an extremely important property since it helps maintenance as the belt can be vulcanized just one time on original installation without the need for a new joint after a certain period of time.

| SIDERFLEX Serie | Elongation at reference load | Elongation at breaking load |

|---|---|---|

| IW-HE | 0,40% | 4% |

| ID | 0,25% | 2% |

Another important mechanical property is the one connected to cut, impact, and tear resistance: as claimed before, many times SIDERFLEX is chosen over a textile carcass belt because there is a need for increased resistance against “foreign” objects falling into the steel cord belt top cover.

Longitudinal cuts and tears are always a cause of belt replacements both in textile and conventional steel cord belts, nonetheless, thanks to its steel weft, SIDERFLEX is more resistant to this kind of damage. At the same time, SIDERFLEX has high impact resistance so the effect of oversized material falling onto the belt at the loading point is absorbed by the flexible steel carcass and the high-quality level of rubber used.

Finally, also corrosion prevention is another important aspect to be considered. Sometimes, it can happen that steel cord belts are used for the chemical industry, handling fertilizers or similar bulk materials that can cause serious problems connected to corrosion.

Nevertheless, if compared to textile carcass belt, SIDERFLEX assures a superior resistance against steel cord corrosion:

- The adhesion between steel cord and core rubber is obtained thanks to a chemical reaction during the curing process between special chemical compounds present in the rubber and brass (Cu/Zn alloy) covering the cords. In comparison with another coating method (typically Zn), brass assures a higher and more constant adhesion to rubber.

- The open cord construction for IW, HE carcass, and the special design of regular cord used for ID carcass allow the penetration of rubber up to the center of the cords, virtually eliminating the capillary action of moisture.

JOINT

When talking about steel carcass rubber conveyor belts, another important element to be taken into account is splicing method: one remarkable thing to underlined is the fact that SIDERFLEX IW & HE can be spliced according to three different methods:

- Finger joint, is the most frequent and efficient type of joint.

- Insertion joint: is faster than the previous one, but it will increase the joint rigidity.

- Mechanical fastener joints can be used for a short time for easy joint repair. Recommended for HE serie only.

The joint methods described here above assure an excellent level of flexibility of the joint area as there are no reinforcing elements placed parallel to the longitudinal axis of the belt.

The joint is prepared to remove the top cover, bottom cover, and transversal cords and cut the longitudinal cords with special shears or nippers.

The joint elements from each side are connected together: over the fingers, one or two layers of IS are transversally placed covering the whole splice surface. The presence of an Insertion Strip (IS) is necessary to join the fingers among them through the rubber layer placed between cords and IS.

INDUSTRIAL FIELDS

What applications are they excellent for?

As claimed at the very beginning, the choice of a steel cord belt mainly depends on mechanical aspects such as the required breaking load and the overall conveying distance. For this reason, when dealing with the industrial applications where SIDERFLEX can be used, there are many fields where this item can give outstanding performances, such as:

- Agroindustry for cereal or grain conveying

- Cement Plant for clinker and limestone handling

- Chemical Industrywhen handling fertilizers or another specific additive

- Portual Terminals where it becomes necessary to handle any kind of bulk material for ship loading and unloading operations

- Power Plantsconvey biomass or coal to the heating station to produce energy

- Steel Factorieshandle raw/recycled steel to hoven to be cooked and later transformed into a suitable product for future applications

For any further information, you can send an email to sig@sig.it or visit our website and fill in the information request form.

Latest news:

CONTACT US

Discover more about our products

Would you like to have more information about our items?

Fill in the contact form and send your inquiry. One of our experts will get in touch with you as soon as possible.