Rubber Conveyor Belts: their applications and how are manufactured

How many rubber conveyor belt typologies can be manufactured?

SIG can manufacture many different rubber conveyor belts according to the specifically chosen carcass construction:

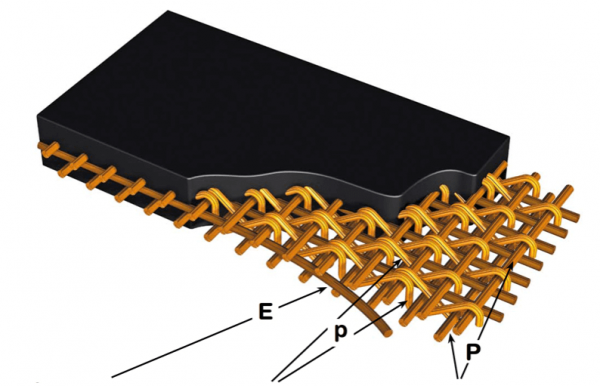

- EP belts, both for horizontal and vertical conveying

- EP belts with a steel transversal reinforcement in the top cover

- steel cord belts that are suitable for flat and vertical material handling.

What is a rubber conveyor belt main application?

A conveyor belt main application is the handling of bulk materials for heavy industries. It is the most technological and suitable method of material conveying as it prevents relying on wheeled vehicles to transport bulk items.

How are rubber conveyor belts manufactured?

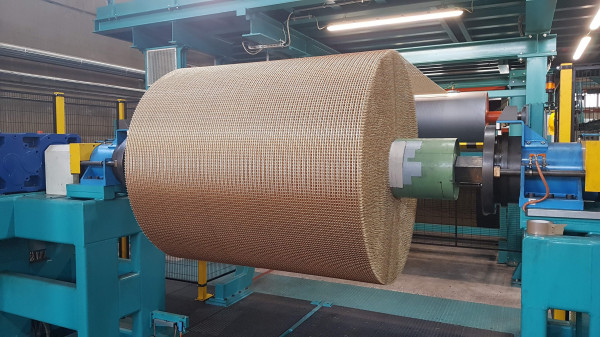

Rubber conveyor belts are manufactured through a calendering and vulcanizing process: during the first one, belt carcass (which could be textile or made by steel) is coupled with the chosen rubber compound to create the raw belt. In the second one, raw belts undergo a vulcanizing process to create the ending product.

Request a custom quote. Contact us at sig@sig.it.

Where can the installation of rubber conveyor belts benefit the most?

Surely, an industrial field where installing rubber conveyor belts to handle bulk material can give many important advantages to the mining industry. Mines (the sites with important mineral fields) may be discovered in the middle of a desert or inside an uncomfortable area in a canyon, in a forest, or at the foot of a mountain range.

In such difficult conditions, where installing complex industrial buildings to extract material or using trucks to transport goods could face many serious problems due to concerned area topography, relying on a conveyor system (which of course would be equipped with rubber conveyor belts) could stand for the most suitable solution overcoming many stumbling-blocks.

What are the functions of rubber conveyor belts in the mining industry?

Up to this moment, it has only been claimed that rubber conveyor belts can represent an important solution to overcome many problems connected to handling just extracted bulk goods inside mines, due to mining areas' topography.

Notwithstanding, how can rubber conveyor belts be used in the mining industry? In which ways can they be used?

To properly answer these questions, it can be useful to analyze and consider all the different operations that may involve such industrial equipment. Therefore, it is necessary to focus on:

- Extracted material handling – once bulk goods such as bauxite (see photo at right), gold or silver, and many more have been extracted, it is necessary to convey it to an area where it could be refined, washed, or loaded on other conveyor systems/trucks. To summarise, at this stage, rubber conveyor belts can be used to simply handle materials outside the mining area.

- Material handling to other plants – once material has been carried outside the mining area, it may undergo specific industrial processes such as washing or refining. Therefore, it would be necessary to handle these goods up to a specific industrial plant and rubber conveyor belts could properly be used to let this process take place;

- Material handling to the port terminal – immediately after the potential industrial process or directly after mining extraction, bulk goods can be then transported to a port terminal to be later shipped to other countries or other industrial plants. In this situation, especially if the distance between the mining site/industrial plant and the port is really important meanwhile facing a desert area, for instance, using rubber conveyor belts can be the most suitable solution to accomplish this task.

- Ships loading operations – last but not least, another important operation to take into account is the one concerning ships loading at port terminals where goods may be shipped to other countries or industrial plants. So, for everything concerned, rubber conveyor belts could be installed to properly execute many different but extremely important operations to let extracted bulk goods be handled most suitably.

So, for everything concerned, rubber conveyor belts could be installed to properly execute many different but extremely important operations to let extracted bulk goods be handled most properly.

What are the main advantages guaranteed relying on rubber conveyor belts?

Using rubber conveyor belts to handle materials in the mining industry can assure many important advantages such as:- No environmental pollution, since it will not be necessary to use trucks to convey goods, therefore there will be no Co2 emission;

- There is no environmental impact since no permanent roads nor infrastructure will be built to let trucks pass;

- An important financial saving as it will not be necessary to pay for trucks’ gasoline or maintenance;

- A continuous working capacity and working flow as well, since material will be handled 24/24 hours with no interruption;

How can a mining industry rubber conveyor belt be chosen?

Choosing the most suitable rubber conveyor belt for a mining application depends on mechanical and technical aspects, such as the conveyor system’s overall length workflow, material abrasiveness, size, and weight as well as.

The first aspect to consider is conveyor system design and length: at this stage, it could be possible to understand if a flat or a tubular rubber conveyor belt may be necessary, and depending on the overall development, then it would be possible to determine if a textile or a steel cord belt could be the most suitable solution. This last choice mainly depends on conveyor system length and potential problems connected to elongation: in fact, when facing long conveying distances (usually more than 500 meters) it would be advisable to rely only on steel cord belts which do not suffer from problems connected to elongation thanks to their excellent longitudinal flexibility.

On the contrary, EP carcass rubber conveyor belts stand for a kind of universal solution that can be transversally used in many different situations that do not involve elongation problems. Once these two design aspects, it is necessary to focus on the handled material and make an analysis to understand its characteristics: abrasiveness, size, and weight. In this way, it would be possible to understand what the most suitable top and bottom cover thicknesses and specific rubber compounds could be.

Latest news:

CONTACT US

Discover more about our products

Would you like to have more information about our items?

Fill in the contact form and send your inquiry. One of our experts will get in touch with you as soon as possible.