Pipe Conveyor: what are and how they are designed

Cement industry is a kind of natural habitat for SIG wide range of products that are suitable for many different industrial applications thanks to their specificity and versatility as well.

TEXTER ® (textile carcass rubber conveyor belt), SIDERFLEX ® (steel cord belts), ELEMET ® (steel cord elevator belt) and ELETEX ® (textile carcass elevator belt) are extremely used in this field always managing to satisfy customers’ expectations, but perhaps pipe conveyors are SIG most iconic item for such applications, since they are worlwide recoignized as high technological content products.

So, what are pipe conveyors?

PIPEX® and PIFLEX® are conveyor belts designed for tubular conveyor systems equipped with a textile or a steel cord carcass, respectively. The special production method for this important item is the result of exhaustive tests and proper theoretical evaluations which allowed to obtain Pipex and Piflex belts whose main characteristic is a significant transversal flexibility.

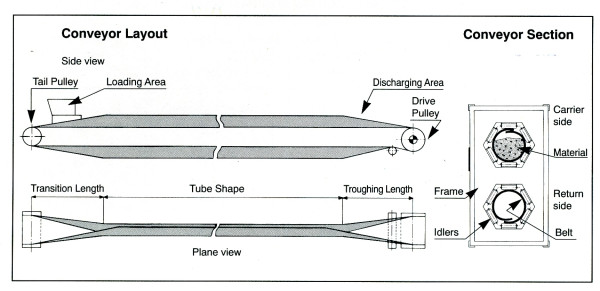

The tubular conveyor system is designed to allow the belt to wrap around the conveyed material while it remains flat at loading, discharging areas and takeup zone.

Consequently, over the full conveying length, Pipex and Piflex belts are shaped into a tubular section by idler frames properly arranged in hexagonal form.

How are pipe conveyors designed?

As previously claimed, PIPEX® and PIFLEX®are tubular shape rubber conveyor belts that can be manufactured with a steel or textile carcass depending on the conveyor system specific technical requirements. What you may have already understood is that pipe conveyors are mainly projected (and used) to avoid dust and material spillage while handling operations.

Therefore, design stage and the layout of the tubular conveyor belt main components are by far one of the most relevant tasks to be accomplished.

As per the conventional troughing conveyor belts, it is worth to design the conveyor plant in accordance with the characteristics of the belt to adopt, especially keeping into consideration the modulus of elasticity of the carcass material. From that derives transition lengths, bending radius as well as the take-up lengths.

On the contrary, when the centre-to-centre distance requires an unacceptable take-up run, it is better to choose the Piflex tubular belt made of a steel carcass requiring wider transition lengths and bending radius. A wrong evaluation of transition lengths and/or bending radius may cause an incorrect closure of the belt and its premature damaging.

To obtain a perfect performance it is furthermore essential to choose the pipe diameter keeping into consideration both the requested capacity and the size of the material; overfilled pipes or too big material lump sizes may determine an obstruction of the materials among the idlers and the damaging of both the belt and the steel structure.

What are the available rubber compounds?

Up to this moment, you have been given some general information about pipe conveyors construction and their layout as well, nonetheless, another crucial element to be analysed is the one concerning specific rubber compound to be used to match with requirements of different industrial applications.

During the years, SIG technical department has been extremely committed in making proper researches and studies to develop and set up new and specific rubber compound to be used. For this reason, when designing a pipe conveyor belt, depending on the handled material characteristics, it is possible to choose between different options as for rubber compounds. A brief explaination is given by the following scheme:

ABRASION RESISTANCE

CL - Standard wear resistant compound, recommended for all ground applications and for the majority of materials, where resistance to abrasion is required.

EC - Extra wear resistant compound, is a superior quality rubber compound, especially designed where maximum resistance to abrasion is required. The characteristics of resistance to cut, tear and ozone cracking, together with long duration, improve the quality of this cover

SELF-EXTINGUISH

BS - Self-extinguish compound, is a rubber compound designed to service both underground and above ground application where safety is fundamental and fire risk is high. It is recommended in particular for coal and potash applications. It is designed according ISO 340 and ISO 284 or equivalent.

AG - Self-extinguish and oil resistant compound, is a nitrile compound suitable for conveyor belts and bucket elevator systems of cereal terminals and silos. This rubber compound provides superior resistances to vegetable oils and animal fats; it is also self-extinguish and antistatic according to ISO 340 and ISO 284 to guarantee high safety to the conveyor plant

OIL RESISTANT

OM - Vegetable oil resistance compound, is a rubber compounds that guarantees a good belt resistance against the chemically aggressive effects due to the transport of materials with moderate oil presence, like corn, fertilizers and general vegetable oily materials. It is expressly designed to resist the terpene of wooden chips and to convey solid urban waste materials.

HEAT RESISTANT

CX - High temperature resistance, assures a medium degree of abrasion resistance; it is formulated for continuous service at temperature of 130 °C with peaks of 150 °C.

MX - High temperature resistance, is a rubber compound assuring good degree of abrasion resistance; it is formulated for continuous service at temperature of 150 °C with peaks of 180 °C.

TX - Superior temperature resistance, guarantees the maximum heat resistance for a rubber compound. It is designed to resist at maximum working temperature of 200 °C with peaks of 300 °C.

Which are pipe conveyors advantages?

Have you ever asked yourself what are the main advantages coming from relying on a tubular shape rubber conveyor belt? If you make a brief comparison between pipe conveyors and traditional rubber belts, it is clear that the first mentioned ones can now easily face and overcome past unsolved logistic and environmental protection problems, such as:

• Horizontal and vertical curves with reduced bending radius

• Little space requirement by compact plant design

• Reduced spillage of materials loaded from the belt

• Dust free transportation

• Low maintenance

The environmental regulations introduced in the last years require the industries to redraw the use of the plants for the transportation of dusty materials; the tubular belts plants are the most suitable for those materials handling where a special care to the environmental protection is needed.

Hence, it becomes evident that pipe conveyors can be considered an environmental friendly products since they are used to prevent dust or material spillage to avoid polluting the surrounding areas. Nonetheless, some products affected by the presence of humidity, such as cement, meet in the tubular conveyor belt system the right technology for their transport in open areas such as loading and unloading wharfs.

At the very beginning, you have been informed that pipe conveyors are perhaps SIG most iconic products for cement industry where these tubular shape items can guarantee astonishing performances. Actually, Pipex and Piflex can be used in many other fields where environmental impact must be reduced and/or where obstacles must be got round.

What can be surely claimed is that pipe conveyors give the maximum of their potential in the fields of: cement factories, power plants, ports and steel making plants.

As far as tubular shape belts installation and splicing are concerned, you should all know that these two extremely important aspects for the correct functioning of a rubber conveyor belts are carried-out following the indications of traditional textile carcass rubber conveyor belts in the case of pipex, whereas for Piflex it is necessary to apply steel cord belts suggestions.

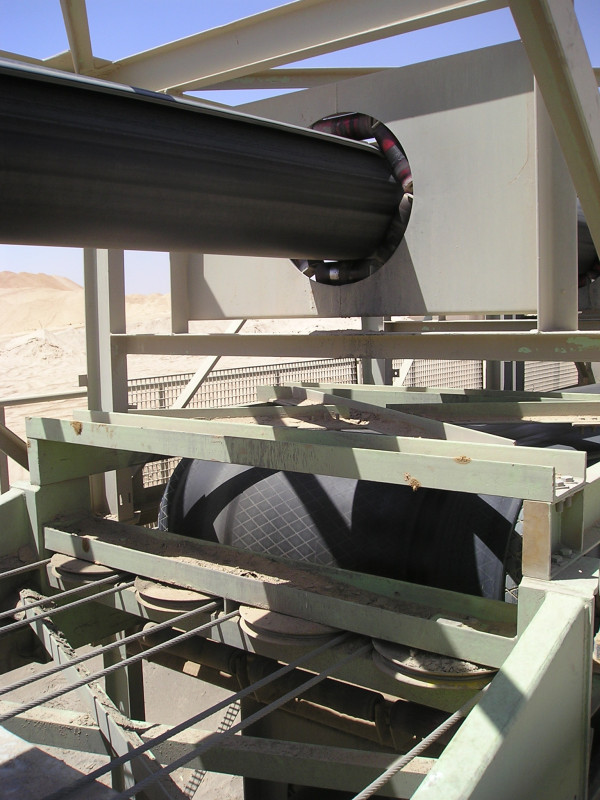

All along its history, SIG has supplied this technologically advanced products all over the world and for many different industrial aims. This year, a 2 km length, extremely strong Piflex (with a breaking load of 1250 N/mm), 1600mm wide has already been supplied to a turkish cement plant (see the picture on right side).

On the countrary, dealing with last year pipe conveyor supplies, between all the different operations successfully accompished, the following ones can be considered the most important:

- 1 km and half length Pipex, equipped with a self-extinguish rubber compound for a coal power plant located in Slovenia;

- A 630 meters length and 1400mm wide Pipex for a canadian cement plant;

- Up to 9 km of a Piflex (1600 N/mm as breaking load) and 2000mm wide for limestone handling for a Middle East port;

- 780 meters of a 1000mm wide Pipex for biomass conveying in a portuguese cement plant.

For any further information, you can send an email to sig@sig.it or visit our website and fill in the information request form.

Latest news:

CONTACT US

Discover more about our products

Would you like to have more information about our items?

Fill in the contact form and send your inquiry. One of our experts will get in touch with you as soon as possible.